-

Products

-

Engine Bus Air Conditioner

Engine Bus Air Conditioner

-

E-Bus Air Conditioner

E-Bus Air Conditioner

-

BTM System

BTM System

-

Refrigeration Unit

Refrigeration Unit

-

Defroster

Defroster

-

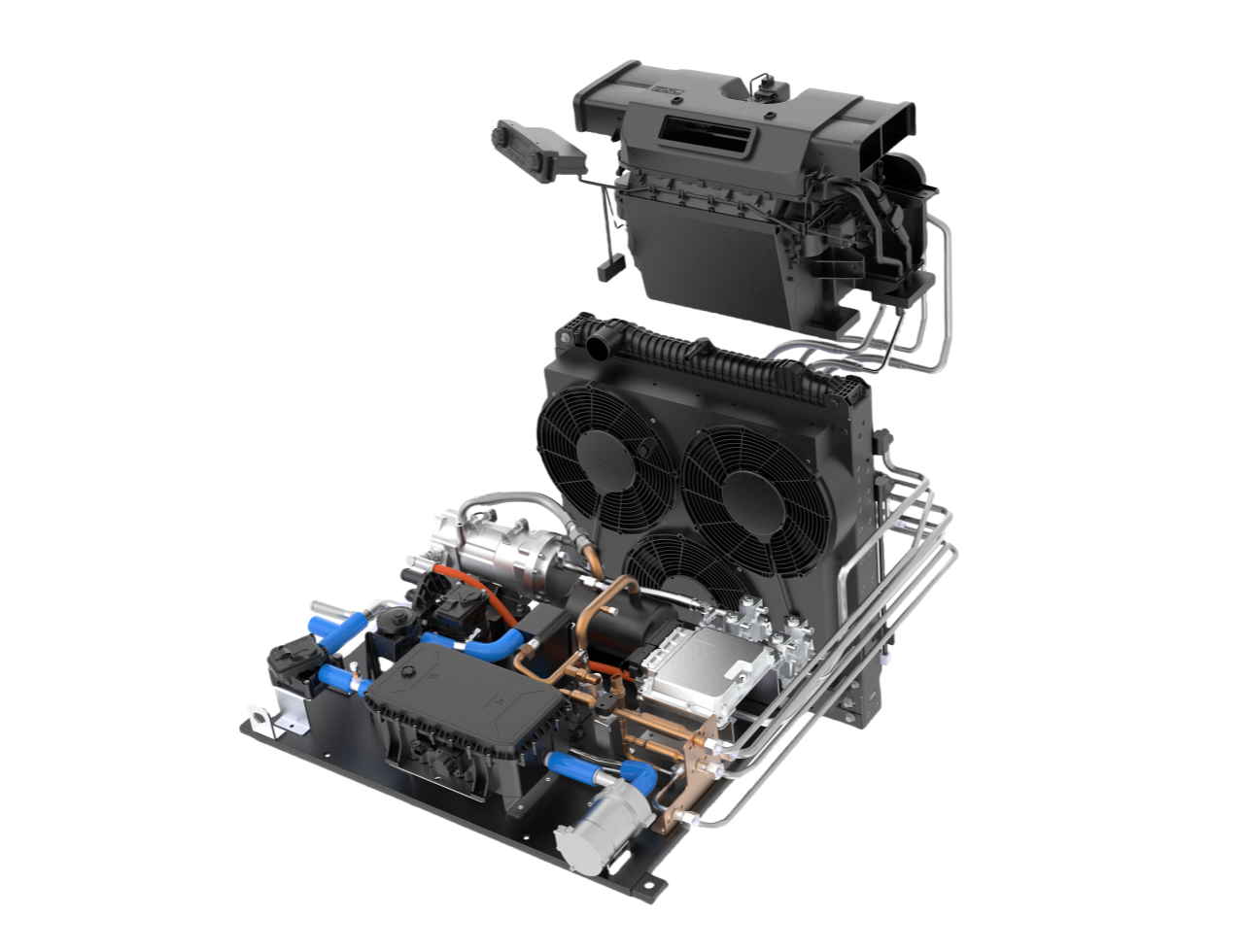

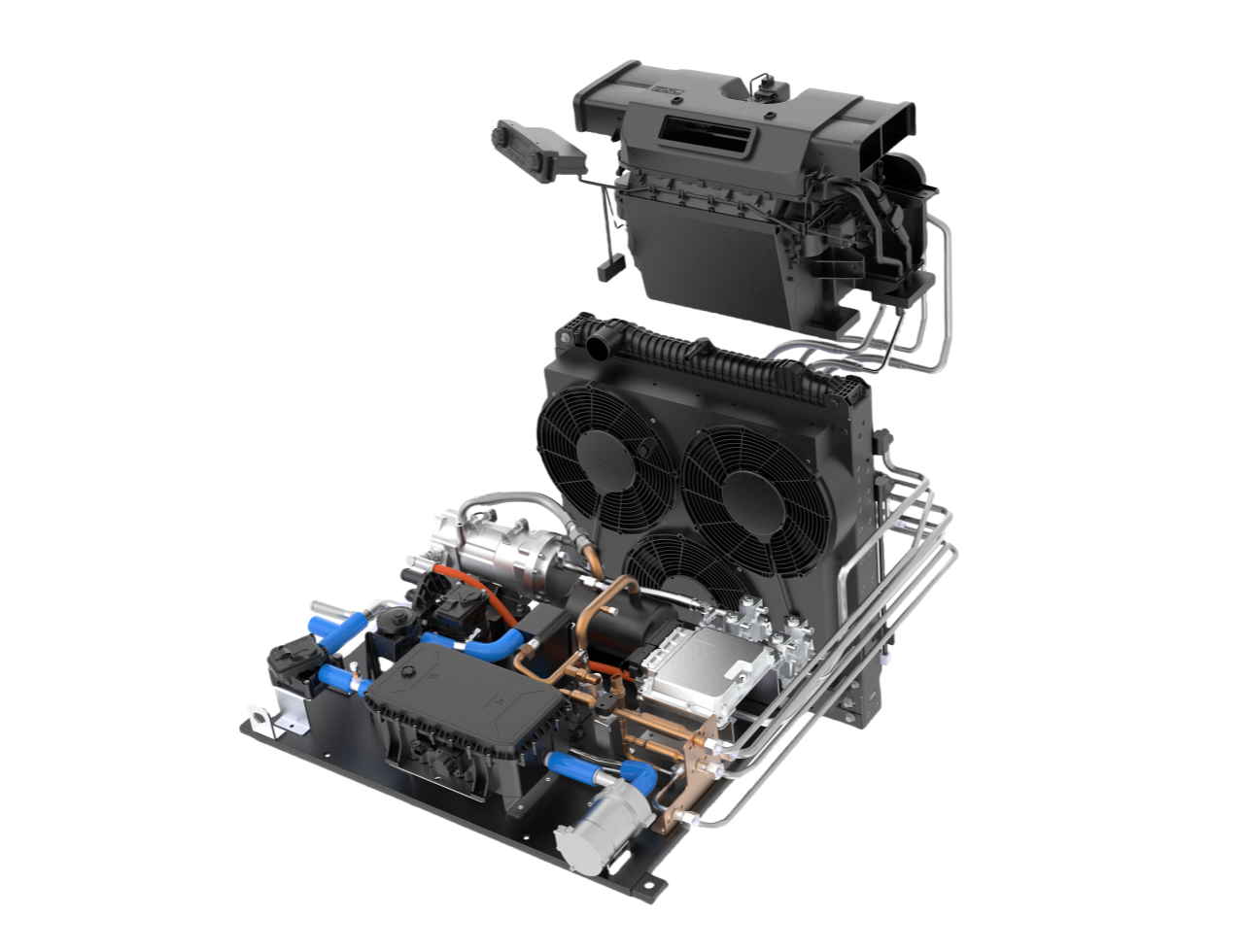

Integrated Thermal Management System & Heat Pump Product

Integrated Thermal Management System & Heat Pump Product

-

Accessory

Accessory

.jpg)

-

Engine Bus Air Conditioner

- About Us

- Support

- Contact Us

1. Introduction of Integrated Thermal Management Electrical System Includes:

(1).png)

The vehicle controller—Supplying high and low power to the air conditioning compressor, PTC, fan pump and other components.

The air conditioning panel—Controling the air inlet and outlet mode of HVAC, the blower speed, and sending instructions for each working mode of the thermal management unit.

The thermal management controller—Collecting relevant temperature and pressure signals to control the compressor speed and the opening of the electronic expansion valve, etc.

The high and low voltage wiring harnesses connecting these components, etc.

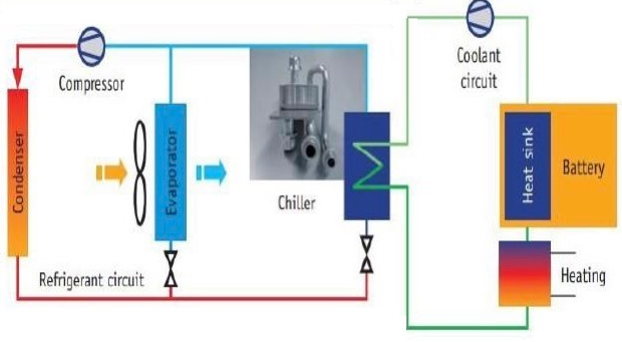

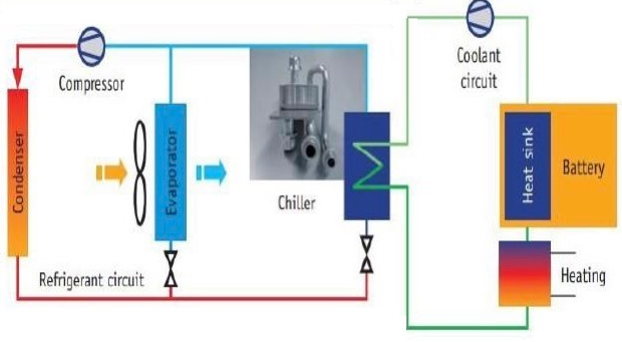

2. The Integrated Thermal Management System Has Four Working Modes:

Cockpit cooling: compressor→outside heat exchanger→solenoid valve→thermal expansion valve→HVAC assembly cold core→gas-liquid separator→compressor;

Battery cooling: compressor→outside heat exchanger→electronic expansion valve 1→plate heat exchanger→gas-liquid separator→compressor;

Combined cooling: compressor→outside heat exchanger→electronic expansion valve 1→plate heat exchanger→gas-liquid separator→compressor;

compressor→outside heat exchanger→solenoid valve-thermal expansion valve→HVAC assembly cold core→gas-liquid separator→compressor;

Heating the cockpit: Turn on the water PTC, and the hot water passes through the air conditioning box heating core to heat the cabin.

The air conditioning and the battery thermal management share components such as compressors and condensers;

Two evaporation systems, respectively used for cockpit air conditioning and power battery temperature regulation;

The battery adopts a secondary heat exchange liquid cooling mode.

(1).png)

3. Advantages of the Cling integrated thermal management system

The electronic expansion valve is used to adjust the refrigerant flow of the system. The two systems can realize three modes of independent operation and joint operation. The corresponding electronic expansion valve/solenoid valve can be closed without cooling demand;

Add a temperature and pressure sensor after the evaporator, couple the cooling logic on the air conditioning and the water temperature control scheme on the battery, and synchronously adjust the opening of the electronic expansion valve 1 and the electronic expansion valve 2, effectively solving the problem of uneven distribution of cooling capacity, and avoiding temperature fluctuations in the vehicle and the battery, which is in line with the comfort of the vehicle and the temperature of the battery. It has obvious advantages in terms of temperature control;

Through PID control technology, the speed of the compressor and condensing fan can be accurately adjusted to achieve energy saving;

Compared with the independent battery thermal management system, it can effectively reduce the weight and cost of the product while meeting the product requirements;

Adding multiple protections such as temperature, pressure, current, and voltage to the system can identify system operation risks in advance and effectively improve product operation reliability and safety;

The unit adopts the CAN communication network, and the unit operation data can be uploaded to the instrument in real time, and remote fault diagnosis and processing can be achieved through intelligent networking, which is convenient for detecting the unit operation status and after-sales troubleshooting.

As a professional electric bus air conditioner manufacturer in China, CLING bus HVAC offers all kinds of bus air conditioner solutions for 6-25m bus, citybus, coach, school bus, shuttle bus, special vehicles and battery thermal management system, on vehicle refrigeration unit with shortest leadtime possible! 20 years professional experience and reputation guarantees the extraordinary performance!

The electronic expansion valve is used to adjust the refrigerant flow of the system. The two systems can realize three modes of independent operation and joint operation. The corresponding electronic expansion valve/solenoid valve can be closed without cooling demand;

Add a temperature and pressure sensor after the evaporator, couple the cooling logic on the air conditioning and the water temperature control scheme on the battery, and synchronously adjust the opening of the electronic expansion valve 1 and the electronic expansion valve 2, effectively solving the problem of uneven distribution of cooling capacity, and avoiding temperature fluctuations in the vehicle and the battery, which is in line with the comfort of the vehicle and the temperature of the battery. It has obvious advantages in terms of temperature control;

Through PID control technology, the speed of the compressor and condensing fan can be accurately adjusted to achieve energy saving;

Compared with the independent battery thermal management system, it can effectively reduce the weight and cost of the product while meeting the product requirements;

Adding multiple protections such as temperature, pressure, current, and voltage to the system can identify system operation risks in advance and effectively improve product operation reliability and safety;

The unit adopts the CAN communication network, and the unit operation data can be uploaded to the instrument in real time, and remote fault diagnosis and processing can be achieved through intelligent networking, which is convenient for detecting the unit operation status and after-sales troubleshooting.

As a professional electric bus air conditioner manufacturer in China, CLING bus HVAC offers all kinds of bus air conditioner solutions for 6-25m bus, citybus, coach, school bus, shuttle bus, special vehicles and battery thermal management system, on vehicle refrigeration unit with shortest leadtime possible! 20 years professional experience and reputation guarantees the extraordinary performance!

If you have any questions please don't hesitate to contact us.

E-mail: marketing@clingac.com

Phone: +86 18736032501

Get A Free Quote!

x

Youtube

Youtube

Facebook

Facebook

Linkedin

Linkedin

Instagram

Instagram