-

Products

-

Engine Bus Air Conditioner

Engine Bus Air Conditioner

-

E-Bus Air Conditioner

E-Bus Air Conditioner

-

BTM System

BTM System

-

Refrigeration Unit

Refrigeration Unit

-

Defroster

Defroster

-

Integrated Thermal Management System & Heat Pump Product

Integrated Thermal Management System & Heat Pump Product

-

Accessory

Accessory

.jpg)

-

Engine Bus Air Conditioner

- About Us

- Support

- Contact Us

Core Components of Bus Air Conditioning and Their Functions

.jpg)

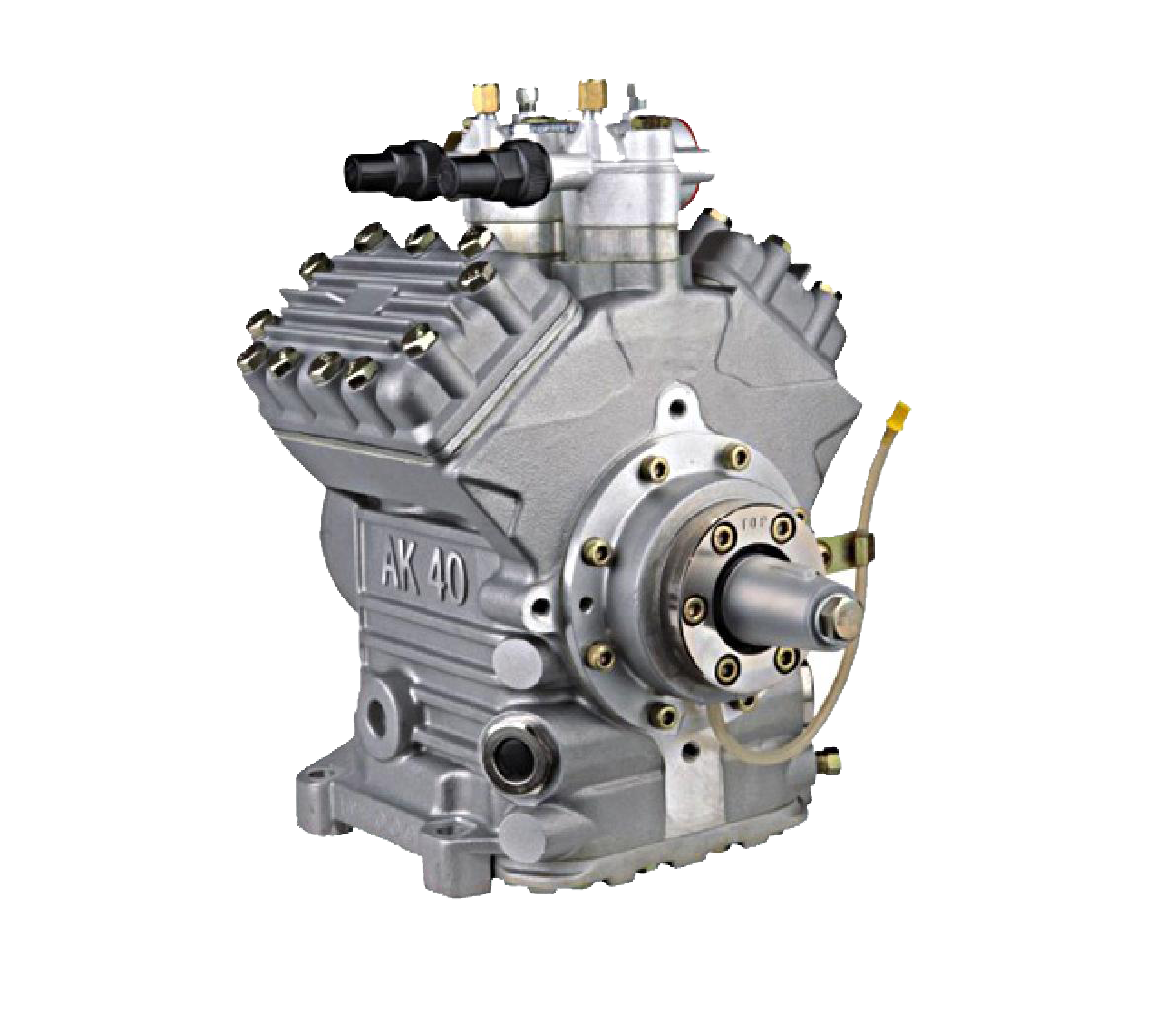

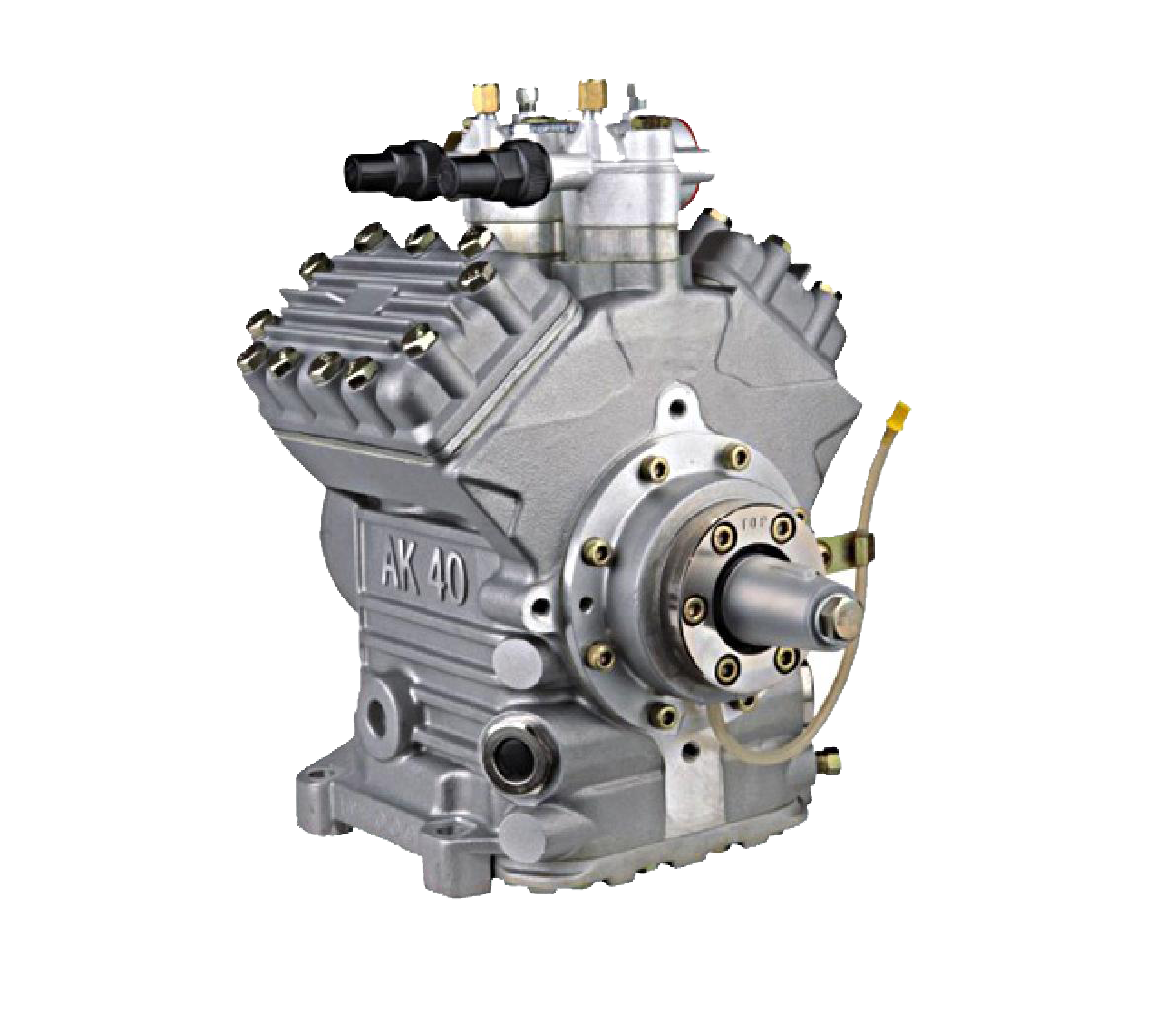

1. Compressor

.jpg)

1. Compressor

Function: The "heart" of bus air conditioning system, compressing low-temperature and low-pressure gaseous refrigerant into high-temperature and high-pressure gas to provide power for the refrigeration cycle.

Type: Common types include scroll, piston or screw compressors.

Criticality: The efficiency of the compressor directly affects the refrigeration capacity and energy consumption.

2. Condenser

Function: Cool and condense the high-temperature and high-pressure gaseous refrigerant into liquid, releasing heat to the outside environment.

Structure: Usually aluminum finned tubes, with fans for forced heat dissipation.

Related components: Works with the condensing fan, and the heat dissipation efficiency affects the system performance.

3. Evaporator

Function: Liquid refrigerant evaporates here to absorb heat and cool the air in the car (blown across the evaporator surface by the fan).

Location: Installed in the air box in the car, directly determines the air supply temperature.

Additional function: Some models also have dehumidification function.

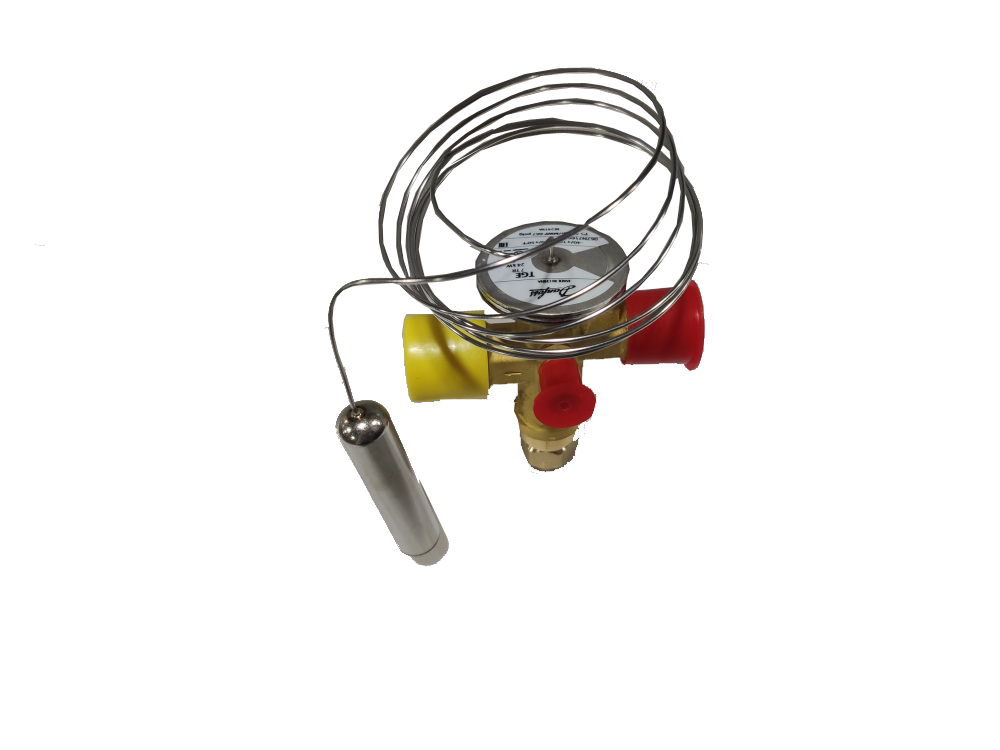

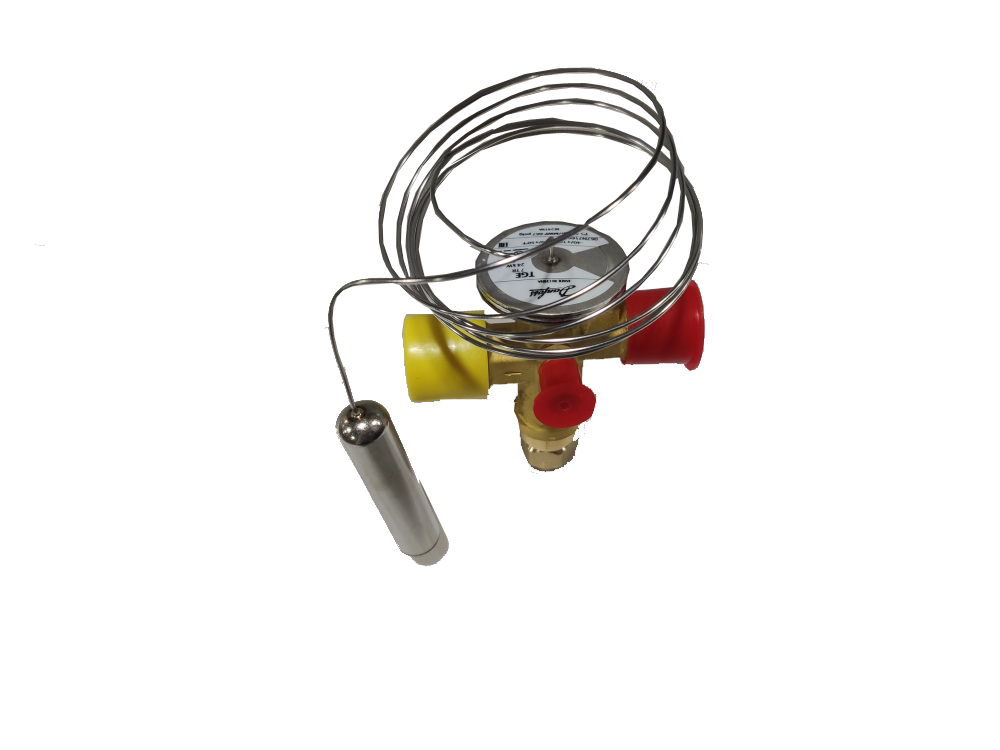

4. Expansion valve (or throttling device)

Function: Control the refrigerant flow and reduce the pressure, so that the liquid refrigerant is atomized into a low-temperature and low-pressure state and enters the evaporator.

Type: Thermal expansion valve (TXV) or electronic expansion valve (EXV), the latter has higher accuracy.

Regulation mechanism: Automatically adjust the opening according to the evaporator outlet temperature.

5. Liquid storage dryer/gas-liquid separator

Liquid storage dryer (for expansion valve system):

Stores excess refrigerant, filters impurities, and absorbs moisture (to prevent ice blockage or corrosion).

Gas-liquid separator (for throttling tube system):

6. Control system (ECU, sensor, operation panel)

ECU: Automatically adjusts the compressor operation according to temperature setting, ambient temperature, vehicle load, etc.

Sensor: Monitors evaporator/condenser temperature, pressure, vehicle internal and external temperature, etc.

Operation panel: For passengers or drivers to adjust temperature, air volume, mode (cooling/heating/ventilation).

.png)

.png)

7. Condenser fan and evaporator fan

Condenser fan: Forced cooling of the condenser (mostly electric or engine driven).

Evaporator fan: Blows the air in the car through the evaporator (forming cold air) or heater (warm air), with adjustable air volume.

8. Refrigerant

Function: Circulating medium (such as R134a, R407C, R410A or environmentally friendly R1234yf), transfers heat through phase change (gas ↔ liquid).

Requirement: The filling amount needs to be checked regularly, and leakage will cause performance degradation.

9. Heating system (optional, for air conditioning)

Independent fuel heater: Common in diesel buses, burning fuel to heat the coolant, and heating through the heater core.

10. Pipes and valves

High-pressure/low-pressure pipelines: Connect various components, need to be pressure-resistant and leak-proof.

Solenoid valve: Control the on and off of the refrigerant (such as closing the refrigeration circuit in winter).

New energy buses: Electric compressors (directly driven by high-voltage batteries) may be used, and traditional belt-driven compressors are eliminated.

Battery cooling: Some models integrate the air conditioning system with battery thermal management and share the condensing circuit.

These components work together to ensure that the bus can stably provide a comfortable interior environment under complex operating conditions (such as high temperature and high load).

As a professional electric bus air conditioner manufacturer in China, CLING bus HVAC offers all kinds of bus air conditioner solutions

As a professional electric bus air conditioner manufacturer in China, CLING bus HVAC offers all kinds of bus air conditioner solutions

If you have any questions please don't hesitate to contact us.

E-mail: marketing@clingac.com

Phone: +86 18736032501

Get A Free Quote!

x

.png)

Youtube

Youtube

Facebook

Facebook

Linkedin

Linkedin

Instagram

Instagram