-

Products

-

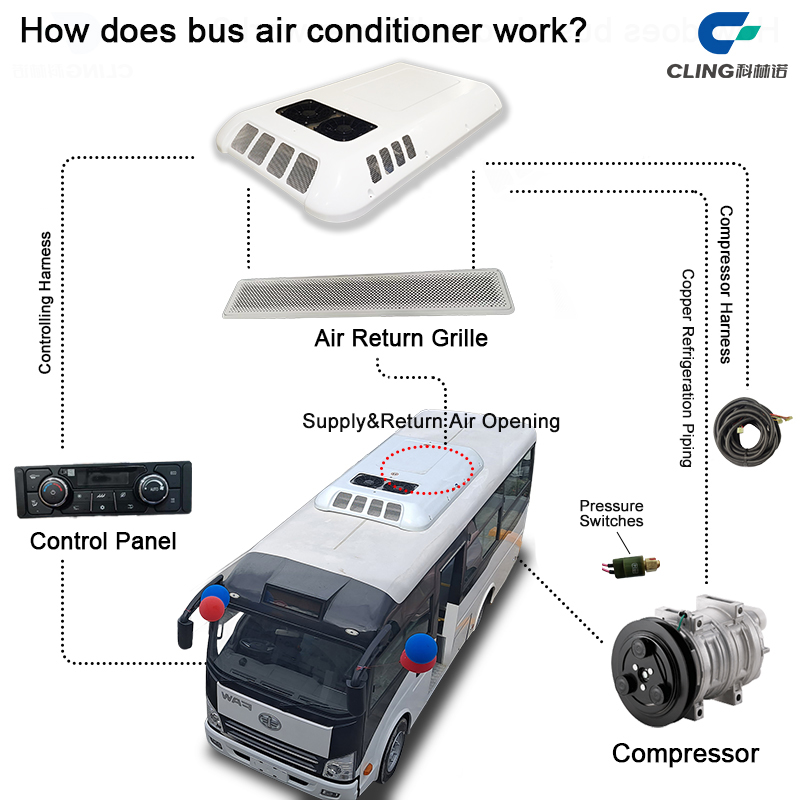

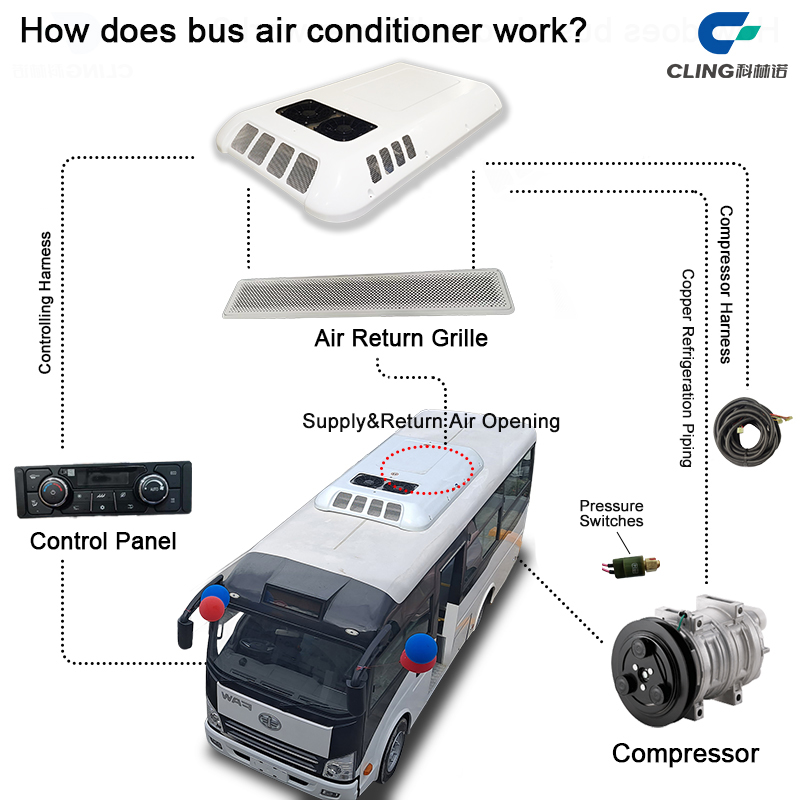

Engine Bus Air Conditioner

Engine Bus Air Conditioner

-

E-Bus Air Conditioner

E-Bus Air Conditioner

-

BTM System

BTM System

-

Refrigeration Unit

Refrigeration Unit

-

Defroster

Defroster

-

Integrated Thermal Management System & Heat Pump Product

Integrated Thermal Management System & Heat Pump Product

-

Accessory

Accessory

.jpg)

-

Engine Bus Air Conditioner

- About Us

- Support

- Contact Us

23-Feb-2025 1Comments

Introduction to the development history of refrigerants in the bus air conditioning industry

Definition and development of refrigerants

Refrigerants are media substances used to complete energy conversion in various heat engines that need to have excellent thermodynamic properties, thermophysical properties, chemical stability, economy, and environmental protection. From 1830 to the present, refrigerants have gone through five development stages, during which the mainstream refrigerants include fluorine-free refrigerants, CFCs-first-generation refrigerants, HCFCs-second-generation refrigerants, HFCs-third-generation refrigerants, and HFOs-fourth-generation refrigerants.

The development of refrigerants can be roughly divided into the following five stages:

The first stage 1830-1930:

Due to social development, people boldly explored refrigerants in the process of artificial refrigeration. The principle of use was to use whatever could be used. CFC-free refrigerants were used. They often had accidents due to their strong instability;

Due to social development, people boldly explored refrigerants in the process of artificial refrigeration. The principle of use was to use whatever could be used. CFC-free refrigerants were used. They often had accidents due to their strong instability;

The second stage 1930-1990:

People's demand for artificial refrigeration increased sharply, and they urgently needed safe and durable refrigerants. At this time, the first generation of chlorofluorocarbons (CFCs) refrigerants such as R-12, which were mainly halogenated hydrocarbons, appeared;

People's demand for artificial refrigeration increased sharply, and they urgently needed safe and durable refrigerants. At this time, the first generation of chlorofluorocarbons (CFCs) refrigerants such as R-12, which were mainly halogenated hydrocarbons, appeared;

The third stage 1990-2000:

The first generation of refrigerants A large amount of ozone in the stratosphere is consumed, and second-generation hydrofluorocarbons (HCFCs) with lower ODP are used as transitional substances in a short period of time, such as R-22;

The first generation of refrigerants A large amount of ozone in the stratosphere is consumed, and second-generation hydrofluorocarbons (HCFCs) with lower ODP are used as transitional substances in a short period of time, such as R-22;

Phase 4 2000-2010:

third-generation hydrofluorocarbon HFCs refrigerants such as R134a, which have no destructive effect on the ozone layer (ODP), but they have a high greenhouse effect (GWP);

third-generation hydrofluorocarbon HFCs refrigerants such as R134a, which have no destructive effect on the ozone layer (ODP), but they have a high greenhouse effect (GWP);

Phase 5 2010 to date:

Due to the high greenhouse effect value of third-generation refrigerants, countries are actively developing fourth-generation fluorine refrigerants HFOs with zero ODP and extremely low GWP, such as R1234yf.

Due to the high greenhouse effect value of third-generation refrigerants, countries are actively developing fourth-generation fluorine refrigerants HFOs with zero ODP and extremely low GWP, such as R1234yf.

Because the cooling capacity requirements of bus air conditioners are much higher than those of household air conditioners and passenger car air conditioners, and most new energy pure electric vehicles are heat pump air conditioners, it is impossible to use secondary heat exchange to isolate and protect the passenger compartment. The use of tube cores and parallel flow cores is far from enough, so Cling currently adopts a two-way research and application solution for CO2 and R1234yf series refrigerants.

Get A Free Quote!

x

Youtube

Youtube

Facebook

Facebook

Linkedin

Linkedin

Instagram

Instagram