-

Products

-

Engine Bus Air Conditioner

Engine Bus Air Conditioner

-

E-Bus Air Conditioner

E-Bus Air Conditioner

-

BTM System

BTM System

-

Refrigeration Unit

Refrigeration Unit

-

Defroster

Defroster

-

Integrated Thermal Management System & Heat Pump Product

Integrated Thermal Management System & Heat Pump Product

-

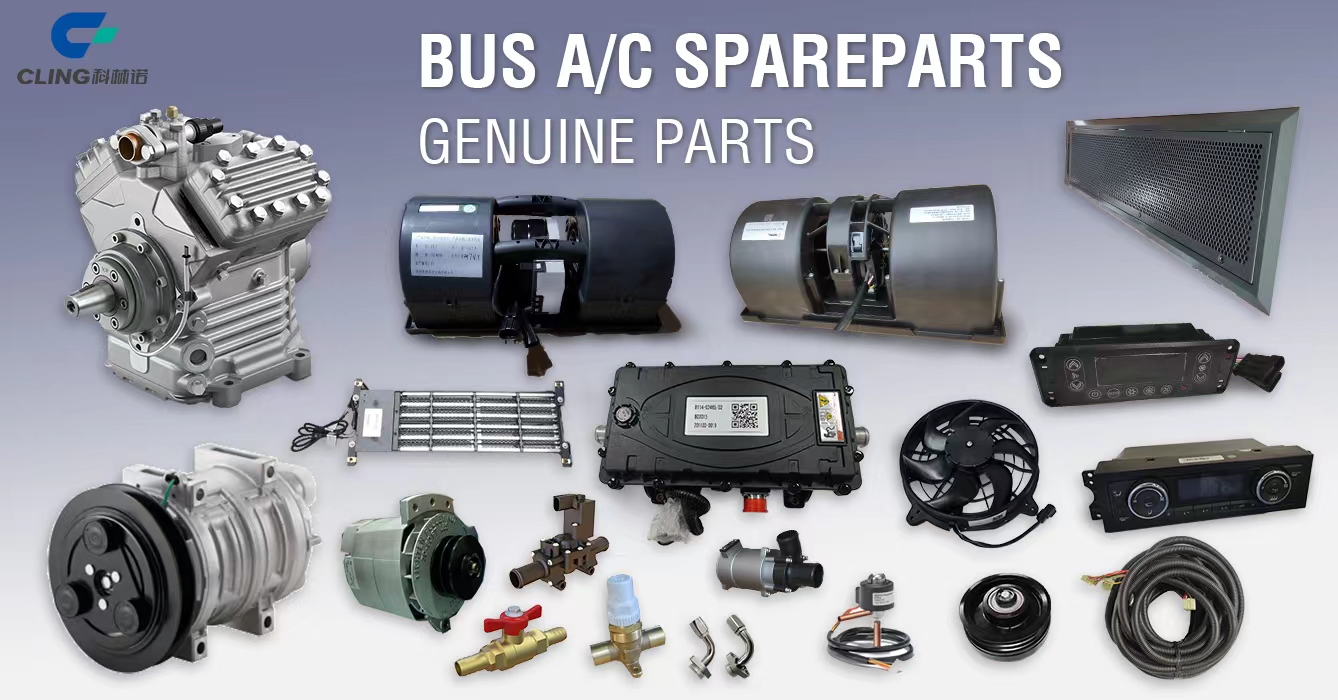

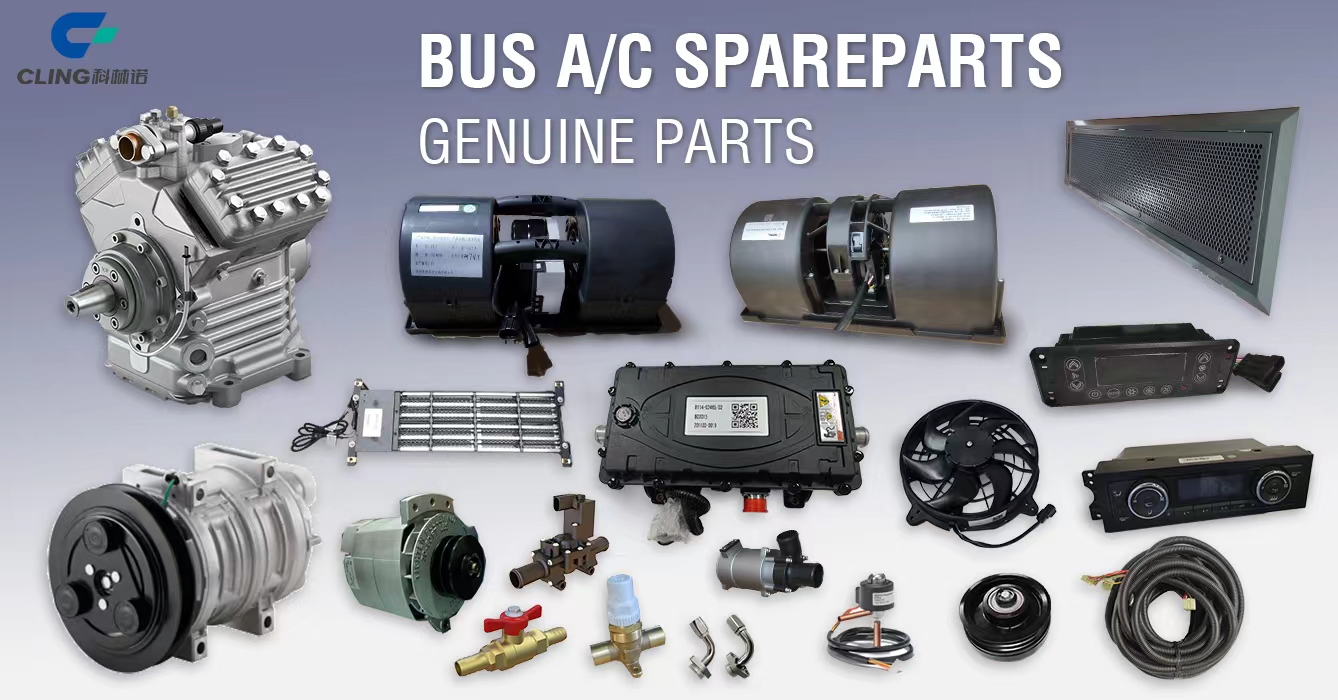

Accessory

Accessory

.jpg)

-

Engine Bus Air Conditioner

- About Us

- Support

- Contact Us

1、What is the bus air conditionier?

The A/C Installed on the bus is bus air conditioner which is very important for driver and passenger comfort of trip.

Bus air conditioner key parts: compressor, condenser, evaporator, piping system and electronic control system.

Bus air conditioning unit condenser:

The condenser is a heat exchange device that condenses the high-pressure and high-temperature refrigerant gas discharged from the compressor into a liquid state after releasing heat through it.

Bus air conditioning unit evaporator:

The evaporator is a device that absorbs heat and vaporizes the refrigerant that has been throttled by the expansion valve to achieve the cooling effect.

2、What role does Bus HVAC System play?

Fresh air : The air conditioner can circulate fresh air, reduce dust, carbon dioxide, bacteria etc, providing passengers with a better environment.

More comfortable trip : In hot summer or cold winter, bus air conditioning controls the bus temperature to make it comfortable for the human body, improving the passenger riding experience.

3、How does the Bus HVAC system work?

The work of the bus air conditioning unit is divided into four processes.

Compression process: It absorbs heat in the evaporator and turns it into a low-temperature and low-pressure gaseous refrigerant. After being sucked and compressed by the compressor, it turns into a high-temperature and high-pressure gaseous refrigerant and is discharged into the condenser.

Condensation process: After compression process, the gaseous refrigerant dissipates heat to the surrounding ambient air through the condenser radiator under the action of the condenser fan, and at the same time condenses into high-temperature and high-pressure liquid refrigerant.

Throttling process: After condensation process the liquid refrigerant passes through the liquid receiver and filter dryer, it is throttled to cool down and depressurize through the expansion valve, and becomes a mixture of low-temperature and low-pressure liquid and gaseous refrigerant and enters the evaporator.

Evaporation process: The mixture of low-temperature and low-pressure liquid gaseous is vaporized in the evaporator. Then it absorbs the heat of the air in the cabin to make the cabin cool by the evaporator fan and at the same time precipitates condensation water. After absorbing heat, the refrigerant evaporates into low-temperature and low-pressure gaseous refrigerant, which is sucked into the compressor and then compressed to complete a refrigeration cycle.

The compressor keeps running to make the above-mentioned refrigeration process circulates continuously. The heat in the bus is taken away by the refrigerant thereby completing the cooling of the bus.

.jpg)

.jpg)

4、How many types of A/C used in buses?

The diesel bus usually uses an engine bus air conditioner. Its advantages are high cooling capacity and cost-effective. but it cannot be used when parking. If you need A/C working when parking, please choose sub engine bus air conditioning.

Followed by the new electric bus air conditioner. Whether its cooling capacity or energy saving ability, it can meet your needs easily.

5、Installation steps of bus air conditioning unit

5.1 Air conditioning unit part

Opening: Check whether the opening on the bus roof is consistent with the size of the air conditioning opening.

Cleaning: Clean the bus roof.

Sealing: Apply sealing insulation sponge around the roof air outlet and return air outlet.

Fixing: Use sealant to fix the corresponding positions of all bolts and shock-absorbing rubber pads.

Installation: Use the corresponding mounting holes and bolts the installation location then apply sealant again to strengthen the fixation to secure it firmly.

Interior: Check the interior of the bus to ensure the sealing insulation sponges on the air outlet and return air outlet are compacted and sealed. Then apply sealant evenly with a thickness of not less than 3mm to strengthen fixation and sealing.

5.2 Pipe installation (drainage pipes, refrigeration system pipes)

Connecting the drainage hose of the evaporation chamber of the air conditioner, fixing the pipe in the both sides of air ducts on the roof and leading it to the outside of bus. Attention: Ensure the water pipes are not compressed or demaged with sharp objects.

To install the refrigeration pipeline, first slowly loosen the blockage at the joint between the evaporator and the condenser to allow the precharged dry nitrogen to overflow. Then connect the refrigeration pipeline to the evaporator and condenser. Apply refrigeration oil to the sealing ring, spreading it evenly.

5.3 Compressor installation

Fix the compressor on chassis and fix the compressor clutch on the compressor bracket. Then connect the drive belt of the compressor to the bus engine.

5.4 Final inspection

Pour in nitrogen to check the tightness of the refrigeration system, then fill refrigerant.

Check all connections.

Start the bus air conditioning system and check its operation.

After running for a while, check the pressure and temperature again.

Finally, cleaning and inspection to ensure that all work has been completed and no parts have been missed.

As a professional electric bus air conditioner manufacturer in China, CLING bus HVAC offers all kinds of bus air conditioner solutions for 6-25m bus, citybus, coach, school bus, shuttle bus, special vehicles and battery thermal management system, on vehicle refrigeration unit with shortest leadtime possible! 20 years professional experience and reputation guarantees the extraordinary performance!

As a professional electric bus air conditioner manufacturer in China, CLING bus HVAC offers all kinds of bus air conditioner solutions for 6-25m bus, citybus, coach, school bus, shuttle bus, special vehicles and battery thermal management system, on vehicle refrigeration unit with shortest leadtime possible! 20 years professional experience and reputation guarantees the extraordinary performance!

If you have any questions please don't hesitate to contact us.

E-mail: marketing@clingac.com

Phone: +86 18736032501

Get A Free Quote!

x

Youtube

Youtube

Facebook

Facebook

Linkedin

Linkedin

Instagram

Instagram